Collaboration: Hultafors I Target group: Electricians

4 weeks, Fall 2018 I Umea Institute of Design

How can the screwdriver be upgraded with new features to improve performance?

specific user focus

attention to detail

quality

trustworthy

> Functionality of product more important than Hultafors identity

> Combination of ergonomics, aesthetics and uniqueness

> Wera and Bahco are seen as biggest competitors

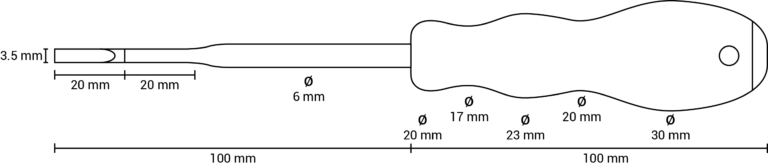

> 3.5 mm flat head most common screwdriver

> Don’t look at tools when reaching for them

> Buying process: “We just get whatever is on the shelves at Ahlsell”

> Bost, Bahco and Expert best brands, because of rounded handles

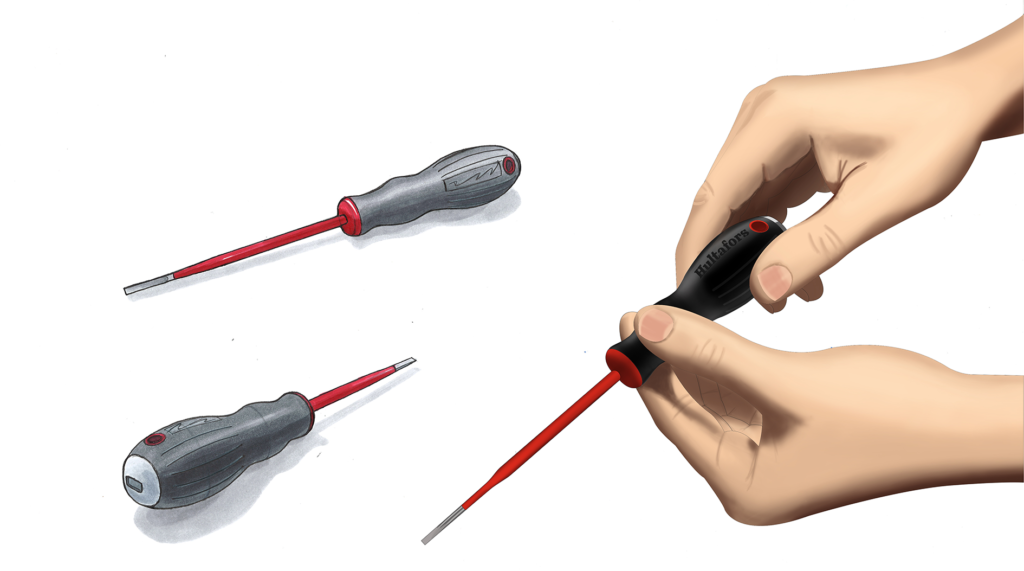

Carrying 4-5 screwdrivers in pockets/belt (additional screwdrivers in backpack)

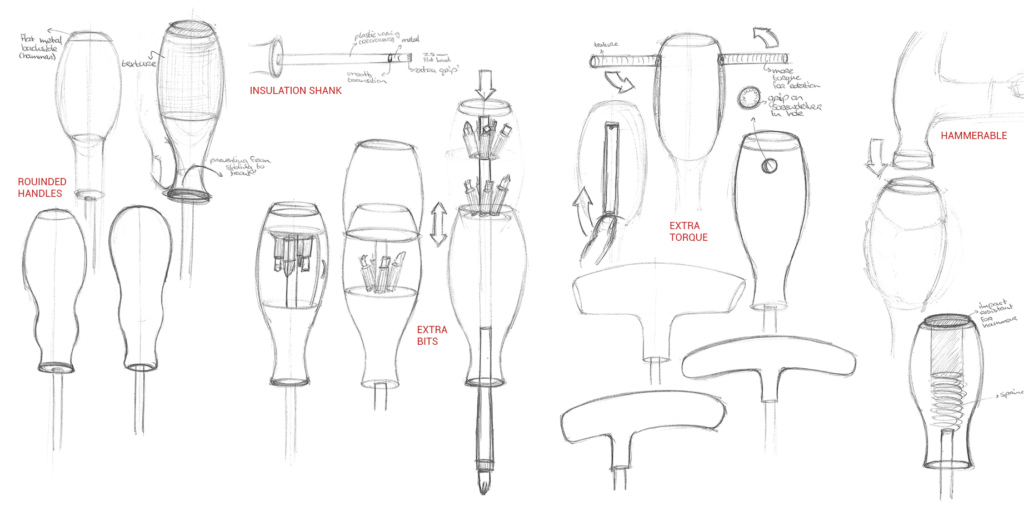

Too long/thick insulation (for reaching narrow spaces)

Screwdrivers with extra bits often too thick

Adding extra torque for rotation

Hammering on top of a screwdriver

bending, adding extra torque) that's why they don't last as long as they could"

Most electricians are wearing thin gloves

Preferable texture fully around and only at back part

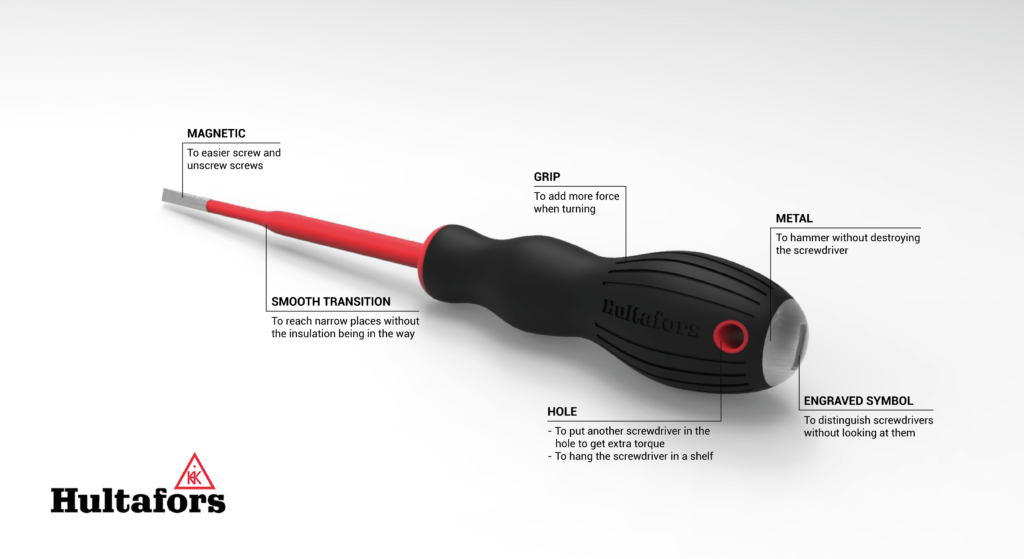

Preferable smooth transition between insulation and metal

- Precision work (for small/medium bits)

- Nice fit, good shape

- Like the grip

- Could be a bit longer

- Too big for normal screwdriver

- Good size if bits are inside

- Hammering part super useful

- Overdesign, always have

more than one screwdriver for

putting in hole for extra torque

- Having hole is definitely

useful

- Almost never use

T-shape screwdriver

- Takes a lot of space in pockets/belt compared

to regular ones

- L-shape screwdrivers

mostly not used

- Just seen as extra

screwdriver to carry,

which is inconvenient

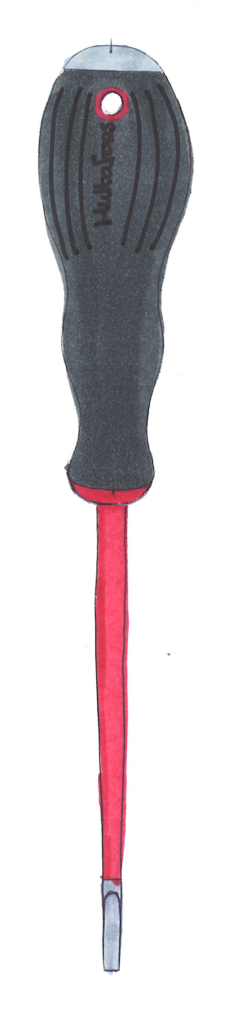

front and back part would be better. Further the front part of the second concept looks really good.

Add hammering part from second concept

Front part based on second concept

Add hole from third concept

More rounded back part

Bit longer handle

Line pattern

Red - Black - Metal

Engraved logo

Hultafors wishes:

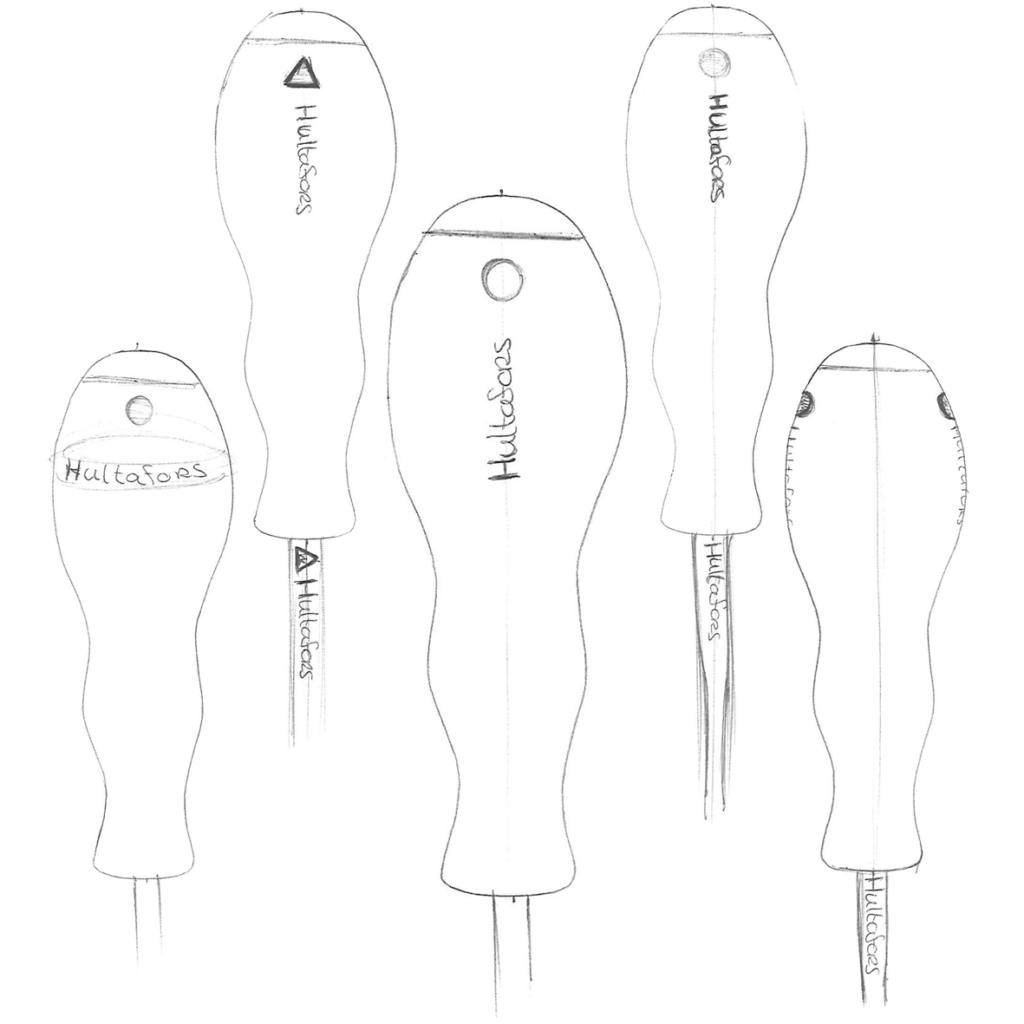

> Logo should be visible if product lays/hangs in shelves

> Preferable logo only once at product, except if it makes sense to have more

Arguments for middle option:

> The easiest way to read text is from bottom to top if product hangs in shelves

> Logo four times on product is too much, decided to place two logos

> In this way the screwdriver can hang with both sides to the front

Arguments:

> Pattern allows extra grip in back, but smooth rotation at front part

> Logo doesn’t stand out too much with rest of screwdriver

> Different look then existing screwdrivers

> Every color is related to one material

(gray-metal, black-rubber, red-hard plastic)

Deprecated: Creation of dynamic property WP_Query::$comments_by_type is deprecated in /home/desireed/domains/desireedriessen.com/public_html/wp-includes/comment-template.php on line 1528